Improve pallet stability with a stretch wrapping machine

Make The Most Of Tons Security With an Advanced Stretch Covering Equipment for Safe Transport

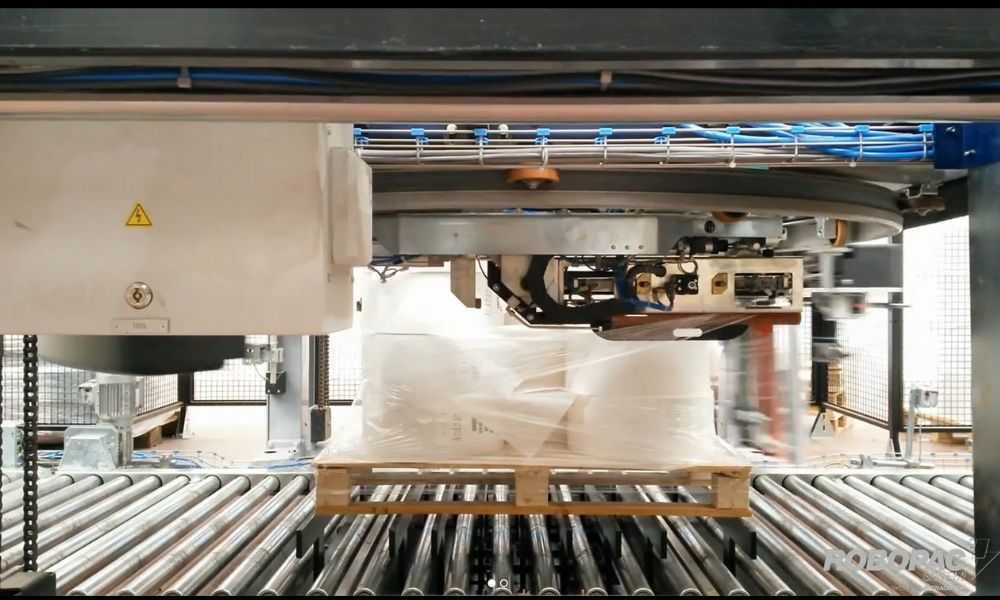

In the world of safe transport, optimizing load stability reigns supreme. Advanced stretch covering makers provide a cutting-edge solution, wrapping up tons with pinpoint precision to avoid shifting during transportation. With a collection of functions such as adjustable film stress and automated functionality, these makers deliver consistent upright and horizontal stability while lessening damages risk. Using puncture and tear-resistant stretch film, services can relax guaranteed their items will arrive undamaged. Yet exactly how do these makers exactly boost tons stability and efficiency? Let's discover.

Understanding the Role of Stretch Covering in Safe Transport

While lots of may forget its value, stretch wrapping plays a crucial duty in guaranteeing the secure transport of items. This process involves making use of a very elastic plastic movie that is covered around items, normally on a pallet. The elastic recovery of the wrap tightly safeguards the items together, protecting against activity throughout transportation.

Trick Functions of Advanced Stretch Covering Machines

In the realm of logistics and supply chain management, advanced stretch covering equipments have actually emerged as a game-changer. These machines are characterized by a number of essential attributes that differentiate them from their precursors. One of the most remarkable functions is their automated functionality. They can cover loads without straight human intervention, lowering labor expenses and enhancing performance.

Advanced stretch covering devices additionally feature pre-stretch abilities. This feature enables the movie to be elongated prior to being related to the tons, optimizing film usage and minimizing costs. Furthermore, these makers have flexible controls for movie tension, enabling modification based upon load shapes and size.

Ultimately, these equipments are equipped with integrated load cells, which accurately measure the weight of the load throughout the wrapping process. This feature guarantees the device changes its procedure based upon the weight, therefore avoiding damages and making certain the lots's secure transport. Therefore, advanced stretch wrapping machines offer a mix of automation, safety, performance, and cost-effectiveness.

Exactly How Stretch Wrapping Machines Enhance Load Security

Ensuring that loads continue to be secure during transportation is a crucial facet of logistics, and one that advanced stretch covering devices master resolving. These makers function by wrapping up the lots in a protective film that holds all products safely together. This minimizes the risk of items shifting or dropping throughout transportation, consequently enhancing lots security.

The equipments use an innovative wrapping method that offers not just vertical yet also straight stability. This dual-axis security further enhances the load and minimizes the likelihood of damages or loss. The uniform stress applied by the equipment throughout the covering process ensures that Click Here the lots is small and safe and secure.

Possible Expense Cost Savings With Effective Stretch Covering

Beyond improving tons stability, advanced stretch covering equipments additionally use considerable capacity for price financial savings. These makers minimize the requirement for manual work, hence reducing payroll expenditures. They additionally work faster and much more efficiently than human beings, resulting in enhanced productivity.

Making use of sophisticated machines makes certain ideal use of stretch movie, which can lead to substantial cost savings in material prices. Manual covering commonly causes wastage because of inconsistent usage of movie. Nevertheless, a device applies the right quantity of film, eliminating wastefulness.

Additionally, the improved lots stability reduces the danger of damages during transport. This can potentially conserve services from costly product losses and associated replacement expenses.

Last but not least, the machines need very little maintenance, which equates right into reduced repair and upkeep expenses.

Selecting the Right Stretch Wrapping Device for Your Company Demands

While the advantages of innovative stretch covering devices appear, selecting have a peek at this website the right one for your specific organization demands can be a complicated job. Different factors require to be thought about - stretch wrapping machine. First of all, think about the type and quantity of products to be wrapped. Devices vary in capacity and adjustability to cover various shapes and sizes of lots. Assess the speed requirements of your operation. High-volume procedures would benefit from automatic machines with higher speeds, while semi-automatic equipments might be sufficient for smaller sized businesses. Thirdly, consider the maker's toughness and maintenance needs. A durable maker that requires marginal upkeep can save prices in the future. Take into account the equipment's assimilation with your existing manufacturing line. It should improve, not disrupt, your process. For that reason, a complete evaluation of these aspects can direct organizations towards the ideal stretch covering device, hence ensuring risk-free transport of their products.

Conclusion

In final thought, advanced stretch covering makers are vital in guaranteeing tons security during transport. Services ought to think about spending in a suitable stretch wrapping machine, even more enhancing safety and security and effectiveness within their supply chain.

Advanced stretch covering equipments provide an discover here innovative service, wrapping up loads with identify precision to avoid changing throughout transit.Making certain that tons continue to be stable during transport is a vital facet of logistics, and one that advanced stretch covering equipments excel in attending to.Beyond enhancing tons stability, advanced stretch covering equipments additionally offer substantial capacity for expense financial savings. High-volume operations would certainly profit from automated makers with greater speeds, while semi-automatic devices might be adequate for smaller sized companies.In final thought, progressed stretch wrapping makers are vital in ensuring load security throughout transport.